-40%

iU3D Swiss CR10 All metal Hotend Titanium BREAK For Ender 3 /V2 / Pro CR-10 etc

$ 12.81

- Description

- Size Guide

Description

The iU3D has always paid attention to product quality.We are developing products and strive to improve quality.We will not give up our reputation because of the many cheap products on the market.

We believe that only high-quality products can ensure the quality of your work and bring safety to your work.

Some of our products may be more expensive than others, but please trust our quality and believe that you will not regret it after receiving the goods.

Our Swiss CR-10 Hotend has better quality and appearance than other heat resistance on this website.

We choose the best materials that can be found in the market, coupled with high-precision CNC machining, and strict quality assurance can bring this high-quality HOTEND Kit.

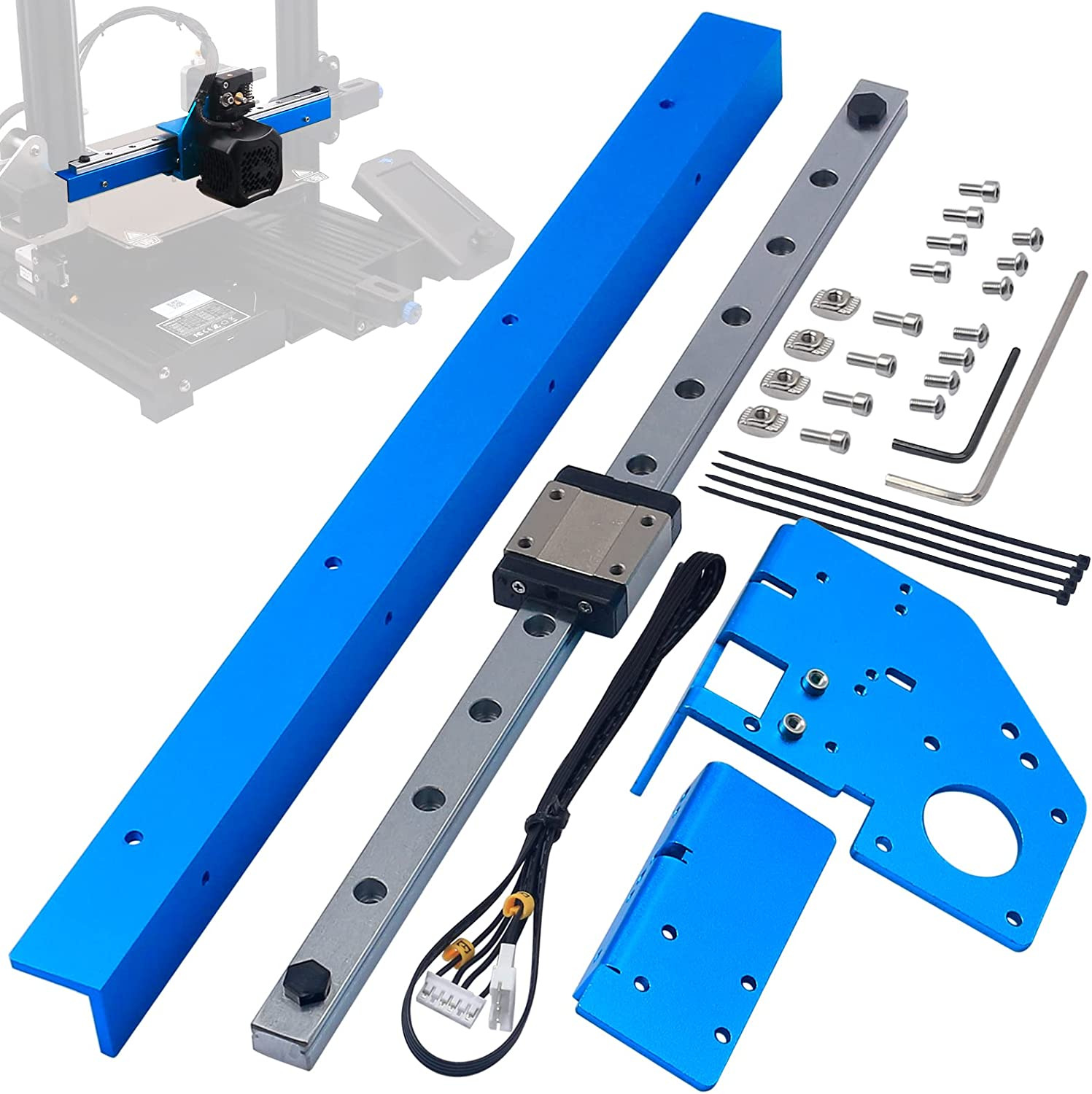

iU3D Swiss CR10 Hotend

This product only supports 1.75mm filament!!!

▉Compatible:

Compatible with CR-10S

Compatible with CR-10S -S5

Compatible with CR-10S -S4

Compatible with CR-10

Compatible with CR-10 -MINI

Compatible with CR-20

Compatible with CR-20 PRO

Compatible with Ender2

Compatible with Ender3

Compatible with Ender3 PRO

Compatible with TronXY X5S

Compatible with Tevo Tornado

Compatible with Alfawise U20

Recommended slicer setting:

retraction speed over 80MM/S

retraction length 2.5-4MM

If you are facing PLA clogging problem, please try the followings:

1. Increase the retraction speed. The speed may have being limited in the firmware try to change it. G-command "M203 E200"

2. Increase the extruder acceleration. Check your firmware settings. G-command "M201 E9000"

3. Reduce the retraction length. It depends on your machine setup.

4. Increase the nozzle temperature by 5-10 degrees.

5. Do not install the 2 screws for support the heatblcok like the stock hotend on the CR-10 printer.

6. Make sure that there is no gap between the heatsink and the heat breaker.

▉

NOTE:

We found that many customers do not know how to properly install the nozzle.

Remember the core issues in the installation process.

Just make sure your nozzle and HEAT BREAK front end are tight and sealed. Otherwise, the filament will leak along the screw holes.

Package list:

ALL CR10 upgrade Kit:

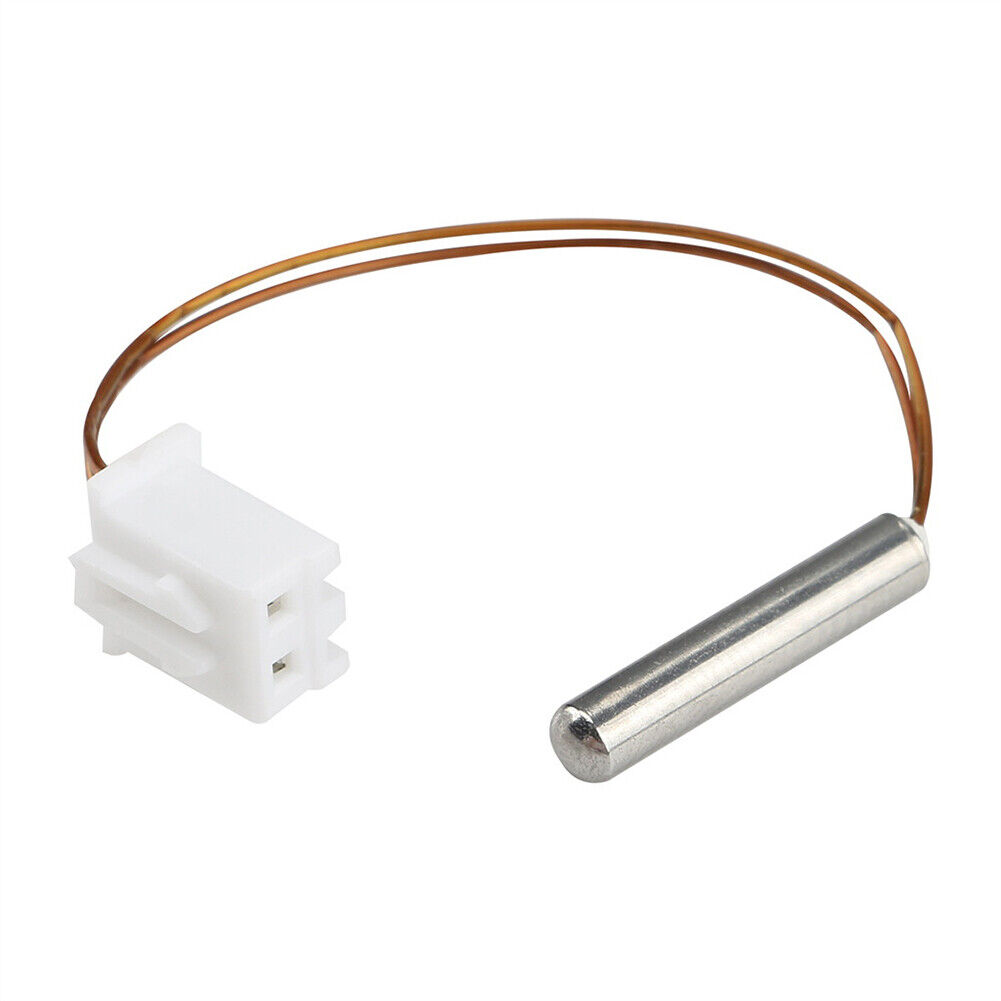

·CR-10 HeatSink X 1

·CR-10 Titanium alloy heat break X 1

Brass nozzle kit:

·CR-10 HeatSink X 1

·CR-10 Titanium alloy heat break X 1

·CR-10 Aluminum Heater Block X 1

·0.4MM MK8 Brass Nozzle X 1

GIFT: MK8 silicone socks X 1

Hardened steel Nozzle kit:

·CR-10 HeatSink X 1

·CR-10 Titanium alloy heat break X 1

·CR-10 Heater Block X 1

·0.4MM MK8 Hardened Steel Nozzle X 1

GIFT: MK8 silicone socks X 1

Plated Copper nozzle kit:

·CR-10 HeatSink X 1

·CR-10 Titanium alloy heat break X 1

·CR-10 Plated Copper Heater Block X 1

·0.4MM MK8 Plated Copper Nozzle X 1

GIFT: MK8 silicone socks X 1

▉

Plated Copper description:

These nozzles and Heater Block are engineered for ultimate high temperature performance.

Made from a special high temperature copper-alloy with a softening point of well above 500°C,

and with much-increased thermal conductivity these copper nozzles are perfect for high temperature applications,

while working perfectly with everyday filaments like PLA, ABS and spoolWorks EDGE.

In addition to high temperature performance these nozzles have an advanced nickel based plating,

considerably reducing the adhesion of plastic to the nozzle.

This is great for everyday filaments keeping things clean and shiny,

but is particularly important at temperatures above 300°C where a silicone sock can't be used.

Copper has more than 3x the thermal conductivity of brass,

and the copper alloy we use has been hardened and treated to reduce the oxidation that occurs in copper at high temperatures.

The higher thermal conductivity will also slightly increase your heat-up times, and can provide tighter temperature control.

This copper-alloy is very temperature resilient, and will not start to soften or anneal until way beyond 500°C,

making it perfect for the high-temperature printing that other nozzles can't handle.

▉Finally

:

Thank you for choosing

iU3D

We will gradually update more high-quality printer accessories,

Hope our customers like and support us.

Your recognition and support are our

our forward momentum

.

If you have any questions, please feel free to contact us via email.

We will reply you within 24 hours and help you solve the problem.